AC Motor

AC motor, driven by alternating current, consists of a stator that generates a magnetic field through alternating current and a rotor that transfers torque to the shaft through the generated electromotive force.

AC motor, driven by alternating current, consists of a stator that generates a magnetic field through alternating current and a rotor that transfers torque to the shaft through the generated electromotive force.

A device, connected to engine crank pulley and belt to convert mechanical rotational motion into electrical energy, supplies stable electricity to the automobile system and charges the battery. The development of high-output and high-efficiency generators is in demand to increase the electric load and improve the fuel economy of automobiles.

It is a device that converts electric energy of the battery into kinetic energy with an electric motor that starts the automobile engine. The development of starter motors with various specifications is in demand along with the development of new engines.

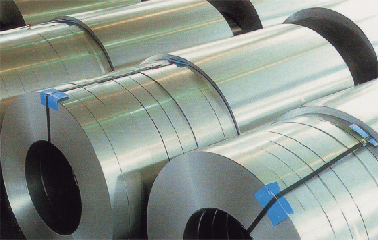

We are equipped with SUT M/C for ultra-precision processing of thin plates from 0.2mm to 1.2mm, such as electric steel and cold rolled steel, and have secured the best quality and technology by accumulating technology through technical exchange with overseas companies. We also have a wide range of materials to meet customer demands.

ELECTRICAL SILICON STEEL & COLD ROLLED STEEL SHEET

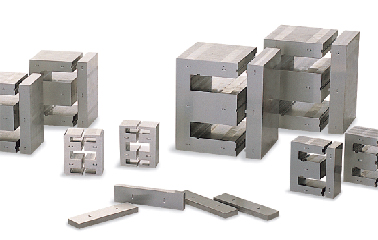

We are equipped with various standard cores and large industrial cores. We respond quickly to develop and mass-produce specialized cores to meet customer demands. As a result of continuous research and development, we have invented block cores of all specifications with superior quality and productivity to provide our customers with a higher competitive edge.

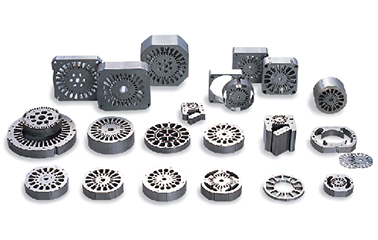

We produce motor cores that are widely used in a variety of applications such as home appliances, automobiles, industrial facilities, and office automation. We are actively responding to customer demands from development to mass production of new products. Since the development of Korea’s first automatic additive tooling of the core die casting in 1991, we have been producing high-quality products through continuous technology development and supplying them to our customers at reasonable prices in a timely manner.

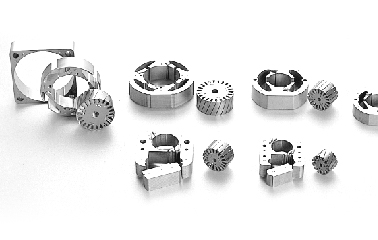

The shaded coil activates motor winding. We have self-developed automation equipment and mass-produce products of uniform quality.

Production Item : □48, ø57, □61, ø68, □74, ø80

In addition to the construction of a new factory, we introduced the overall stator winding facility including insulation paper inserting, coil winding, coil inserting, forming, racing, and inspection for stator winding processing, the core of motor manufacturing technology. We are also producing high-quality products by securing excellent winding technology through technology exchange and cooperation with leading companies overseas.

Production Item : ø121, ø95, ø80, □74, □68, □61, □57, □48

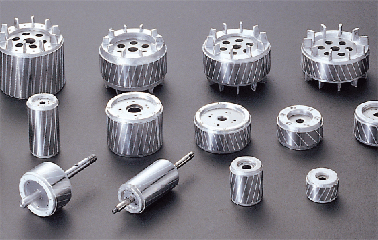

The induction motor core is die-cast into a rotor using aluminum. We have contributed to the improvement of motor quality by supplying high-quality products by introducing 3-stage hydraulic die casts for many years. We also supply our customers with shaft press and outer diameter cutting.

We have brought great innovation to the metal fan industry by supplying high-quality advanced metal fans through technological exchanges with the world’s leading fan manufacturers. By expanding our range of plastic injection moldings, we are responsible for everything related to fans, not just a single product manufacturing, but also finished products of turbo fans, sirocco fans, cross-flow fans, box fans, and ventilators.

We have developed and supplied steel drawing housing to our customers stably to significantly reduce the high material and processing costs associated with existing aluminum injection moldings. We also have high-precision diecasting and CNC machines for products that cannot apply steel due to product characteristics. We will develop motor housings and fan cases as well as any type of product immediately upon customer's requests.